Papyrus and parchment replaced stone and clay as substrates, but it was paper that became that preferred medium. Today paper isn’t a second thought, readily available in many shapes, colors, and weights– that’s because the Chinese perfected the practice first hundreds of years ago. The discovery is accredited to government official Cai Lun in the year 105 CE during the Han Dynasty, though it is thought the process has been around for long and was merely refined by Cai Lun. To make it started with various plants and plant parts harvested and soaking in water. They then cut and beat the soaked bamboo, rags, hemp, bark, and other plant parts into a fine pulp, instead of trying to weave it together into parchment. The pulp was then screened, pressed, and dried to remove the moisture and leaving the pulp in a thin sheet. The cost to make paper was cheap and it lightweight-flexibility became popular quickly. It is believed the Chinese wanted to keep it a secret, but it promptly spread across the world due to globalization and the silk road. The first paper mills popped up in Baghdad around 751 AD, the Islamic world refined the process by replacing the tough plant parts with linen and turning it into mass production. Eventually, Europe caught up with their neighbors to the east and In 1801 filed a patent for London’s Fourdrinier machine. A machine that turned the whole processes into a conveyer belt, creating large rolls of paper that could later be cut to the desired size.

Papermaking hasn’t changed much since the invention of the Fourdrinier machine, the system has been refined and mechanized but the basic idea of the machine is the same. In the 1830s paper started being made solely out of wood pulp and it still is today for the most part. Trees are cut and ground down to fine dust called pulp, then processed by boiling it with sodium hydroxide and sodium sulfide at a high pressure, then beating it till it creates a thick mixture called slurry, it is usually bleached to become white but can also be dyed into any color. It can also be mixed with other mediums for different texture and flexibility, commonly chalk or gum. As the large sheets move through the machine they dry and are rolled up, then sent to be cut and printed on, appearing all over our everyday life. The whole process has become a fine science, using exact measurements and chemistry that produce predictable outcomes so a stack of printer paper is all exactly the same. In a world becoming increasingly more aware of our carbon footprint it is also really common to reprocess paper to make new paper. Meaning you go through the same processes but instead of using wood pulp you used recycled paper. This gives new life to recycled paper and saves on the amount of wood needed to continue making paper, though paper can only be reprocessed a certain amount of times before it useless due to the number of chemicals. The last stage for recycled paper is usually low-grade toilet paper, which instead of being recycled is flushed into the sewers.

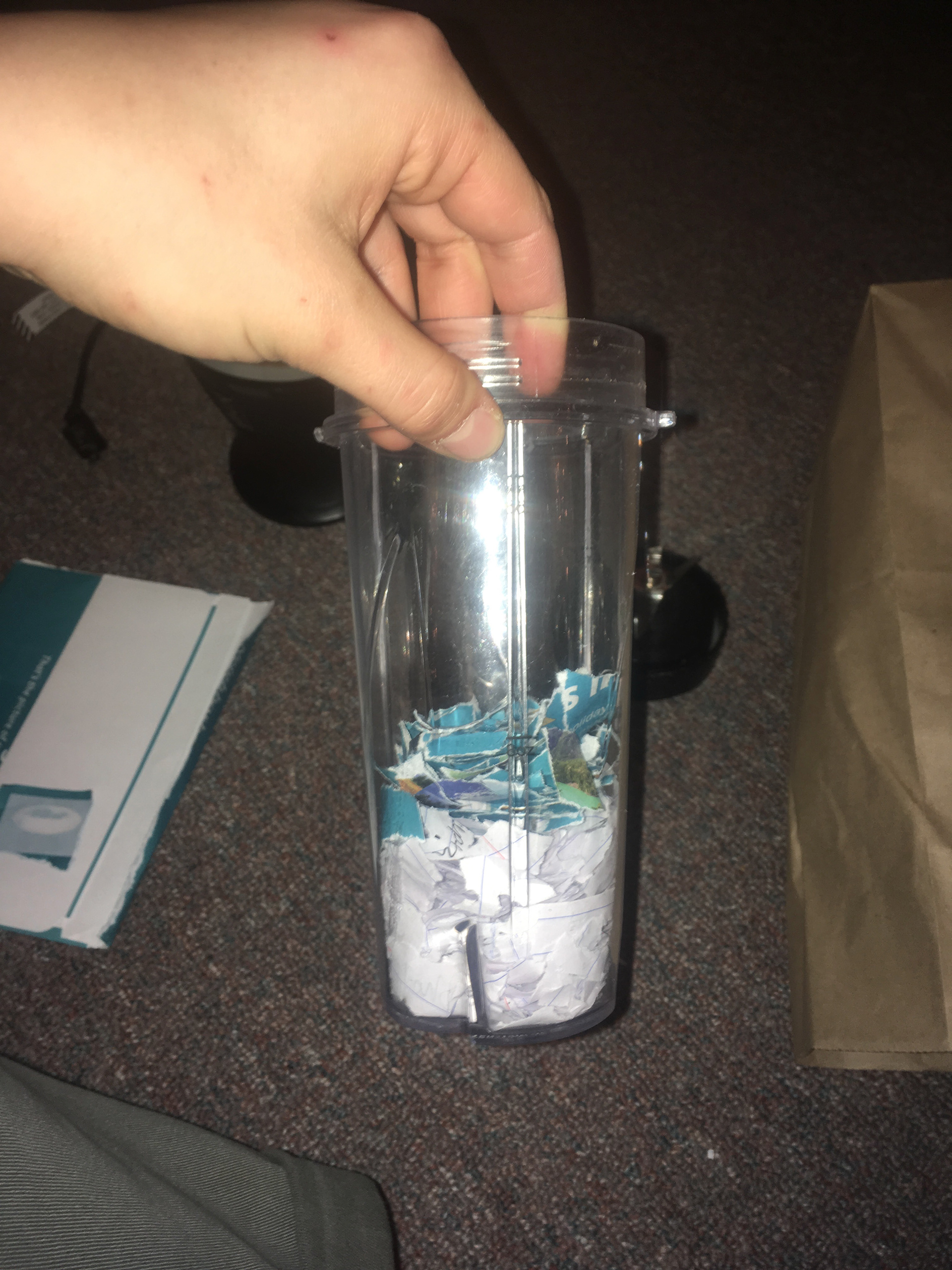

I created my own paper by breaking down recycled paper, pouring it into a screen, flattening it, and waiting for it to dry. The results: not the highest quality paper, but I will definitely be trying to do this again.

Sources

Hoey, Brian. “A Brief History of Papermaking.” Www.BooksTellYouWhy.com, Bibliopolis, 27 Oct. 2016, 9:00AM, blog.bookstellyouwhy.com/a-brief-history-of-papermaking.

“The Rise of an Industry: Papermaking | 1001 Inventions.” 1001Inventions, 1001inventions.com/paper.

Roberts, J. C.. Chemistry of Paper, Royal Society of Chemistry, 1996. ProQuest Ebook Central, https://ebookcentral-proquest-com.ezproxy.spu.edu/lib/spu/detail.action?docID=1185356.